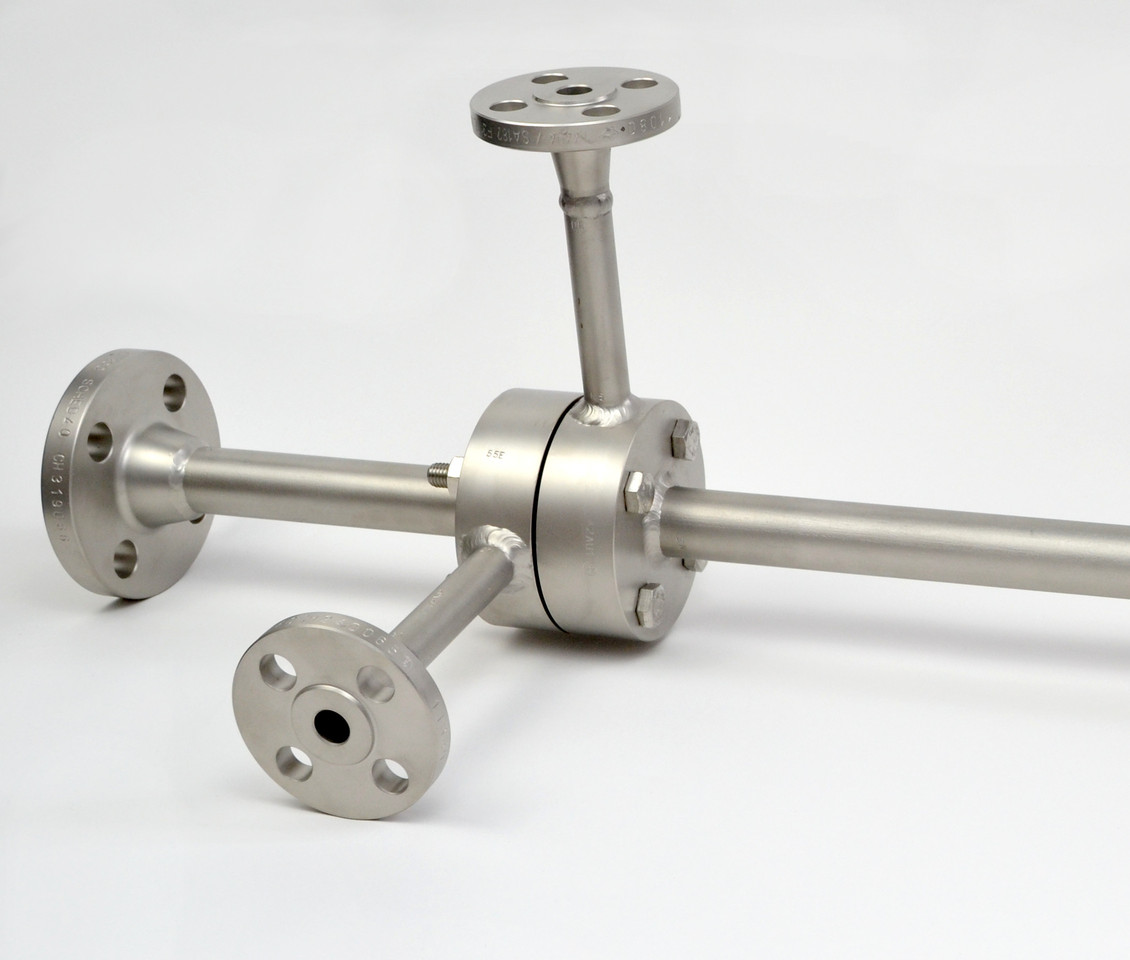

Meter Runs

Description

Meter runs combine a flow element with machined inlet and outlet piping and thus help in reducing disturbances in the flow measurement.

They are mostly used in small pipelines because the influence of pipe roughness on the measurement is significant with smaller diameters. Honed Meter Runs are a prerequisite where accuracy is of paramount importance such as custody transfer.

Design

We offer a large variety of meter run designs. We welcome the opportunity to support you with finding the perfect design for your application.

The meter runs are delivered completely mounted and ready for installation. All meter runs may be offered with flanged ends or weld ends.

Accessories

Condensate Pots

Condensate pots are used in steam applications to achieve a constant condensate level within the pressure taps. If there are any fluctuations which lead to a change in condensate levels the condensate pots help to either reduce the level by backflow of excess liquids or increase the level by additional condensation of liquid.

We can offer it in carbon steel, stainless steel, with or without IBR.

Thermowells

Thermowells are used for a safe installation of temperature sensors into pipes. They prevent the sensor to get in physical contact with the process fluid and are therefore recommended for aggressive fluids and for high dynamical stress which could harm the temperature sensor. Additionally, thermowells offer an easy way to remove the sensor during operation for maintenance.

For differential pressure flow elements with attached inlet and outlet pipes, thermowells are often used to measure the operating temperature downstream in the outlet pipe. The design of thermowells can be divided into the type of process connection (flanged, threaded, welded) and into the type of connection that is utilized to mount the temperature sensor into the thermowell (threaded, welded).

Manifolds

Manifolds are used to close off or purge the pressure taps and to set the zero point of the differential pressure transmitter.

3-way manifolds are able to close off the pressure taps and to set the zero point of the differential pressure transmitter (gas and liquid applications).

5-way manifolds have two additional valves for purging the lines (recommended for steam applications).

We offer all kinds of designs for remote mounting as well as integral connection to the transmitter.