Description

Flow Nozzles are used as DP flow elements for flow measurement of aggressive and non-aggressive gases, steam and liquids. Flow Nozzles may be defined as an intermediate solution between orifice plates and venturi tubes. The permanent pressure loss is lower in comparison to orifice plates. In contrast, the measuring uncertainty may be higher.

Design

Flow Nozzle has a convergent inlet cone, with a short cylindrical throat and without a discharge cone. Due to this contour and shape, Nozzle produces a lesser differential pressure than Orifice Plate, and also a lesser permanent pressure loss for the same flow rate.

Generally, there are three types of nozzles: ISA 1932 nozzles, long radius nozzles and venturi nozzles. Depending on the process conditions, each design has its advantages. Flow nozzles are offered with venturi nozzles flanged ends or weld ends. Nozzles are machined from forged blanks. The measuring accuracy is typically 1 to 2% of full range.

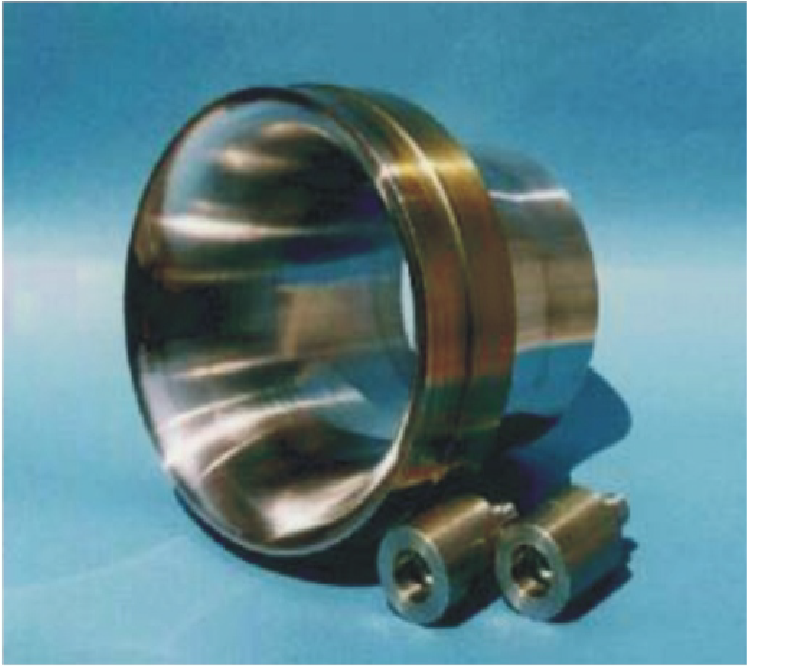

Flow Nozzle (ISA 1932)

Standard flow nozzles consist of circular inlet profile and a cylindrical outlet part. The pressure taps are designed either as single bores in a single carrier ring or as ring chambers with two carrier ring halves.

The measuring uncertainty depends on the process conditions and amounts to approx. 0,8% – 1,2% of the flow coefficient.

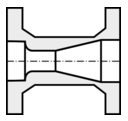

Long Radius Nozzle

![]()

Long radius nozzles consist of a quarter circle inlet profile and a cylindrical outlet part. The pressure taps are located 1D in front of the nozzle and 0,5D behind the nozzle (D = pipe inner diameter).

The measuring uncertainty depends on the process conditions and amounts to approx. 2% of the flow coefficient.

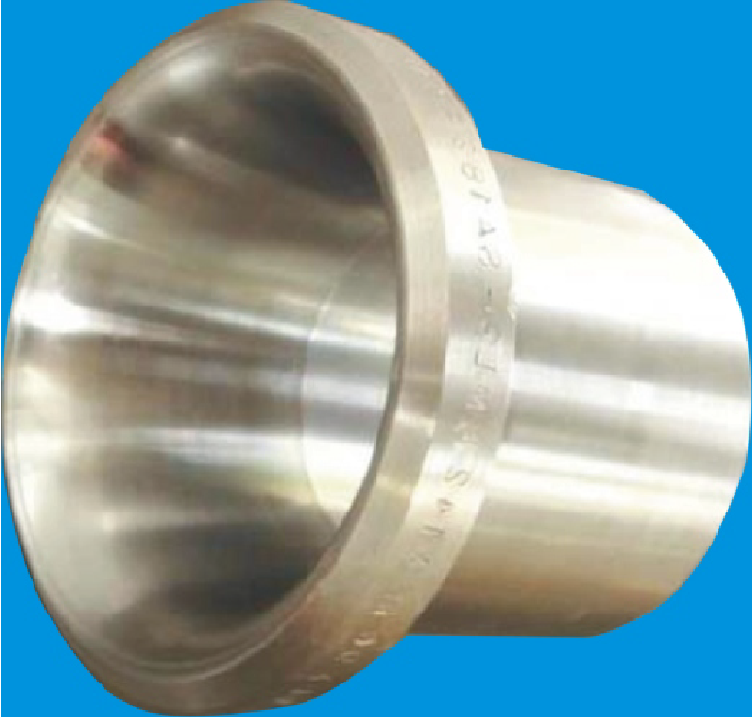

Venturi Nozzle

Venturi nozzles consist of circular inlet profile, a cylindrical middle part and an outlet cone. Normally, the high pressure tap is designed as a single bore. The low pressure tap is usually implemented as four bore holes which end in one ring chamber or annular ring.

Venturi nozzles consist of circular inlet profile, a cylindrical middle part and an outlet cone. Normally, the high pressure tap is designed as a single bore. The low pressure tap is usually implemented as four bore holes which end in one ring chamber or annular ring.

The measuring uncertainty depends on the process conditions and amounts to approx. 1.2% – 2% of the flow coefficient.

♦ Sizes: For line sizes from 80 NB to 400 NB

♦ Pressure Taps:

-

- Plain ends

- Butt weld ends

- Threaded ends

- Flanged ends

♦ Mounting:

-

- Flange type

- Weld-in type (for high pressure applications)

♦ Material of Construction: Forged, Stainless steel or Alloy Steels as per customer request.

Flow Nozzles