Description

Restriction orifice plates use the intrinsic high pressure loss characteristic of orifice plate and is a cost-effective component to achieve a defined pressure loss in a process or in blow-out lines. In special cases they can be used to limit the flow. Restriction orifice plates are suitable for single-phase media. Typical applications include:- Blow Down Flow Control, Pump Recirculation line, Controlled pressurization etc.

Design

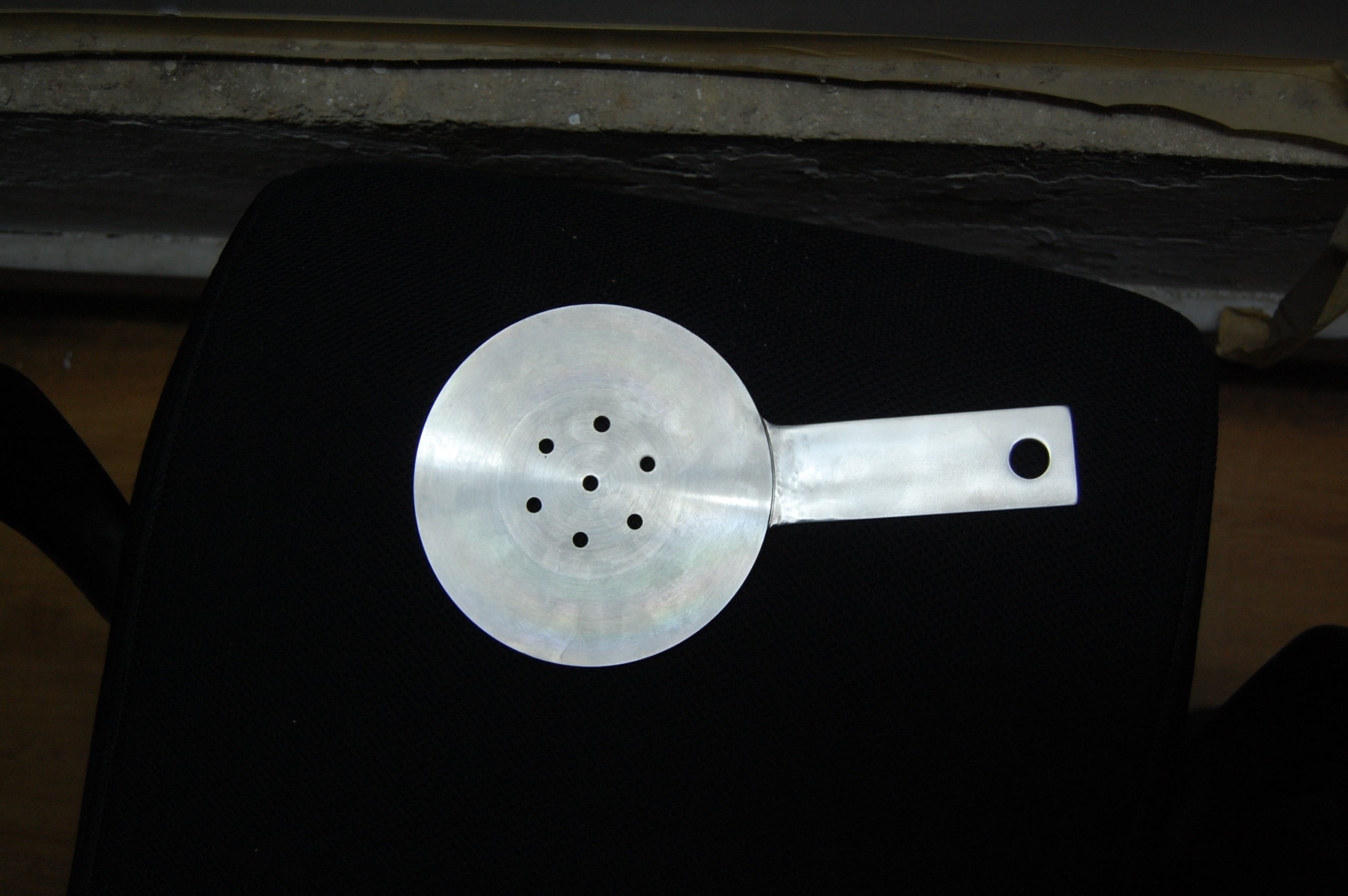

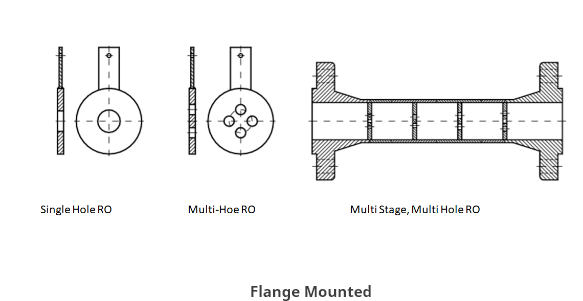

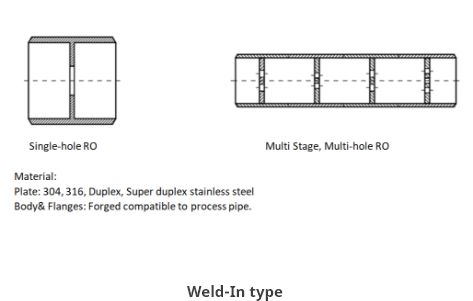

Restriction orifices are normally designed as a simple plate with an attached tag handle. Restriction Orifices may be designed as a single plate with handle for installation between flanges or integral weld-in type. Normally, we offer them with a cylindrical bore hole. In special cases, the bore hole may not be positioned centric.

For simple pressure reduction applications a thin orifice with maximum thickness 6 mm and discharge coefficient 0.6 will be required. In applications where Choked flow is desired, a thick orifice with a high discharge coefficient is required.

In order to achieve a higher durability – especially considering possible cavitation – we offer hardness coatings like Stellite, for extended life.

Restriction Orifice plates are subjected to severe conditions associated with high pressure drops such as noise generation, flashing of fluids into gas, cavitation and choked flow (Sonic Flow). Against such specific process applications, we can offer a multi-hole and/or multistage design. In special cases they may be designed to achieve controlled flow or to limit the flow to a specific value.

Restriction Orifice plates are designed and manufactured as per ISO 5167, AGA and ASME standards.

Design Types

Restriction Orifice